Responding to Climate Change

Information disclosure based on the TCFD recommendations

As one of the specific initiatives to promote sustainable management, the Company has recognized climate change issues as a key management issue and endorsed the TCFD* in support of the TCFD in April 2023. In May 2024, we also joined the TCFD consortium.

The Group will provide appropriate information disclosure and continuous improvement in line with the TCFD’s recommended disclosure themes of “governance,” “strategy,” “risk management,” and “metrics and targets.”

- * TCFD (Task Force on Climate-related Financial Disclosures)

:Task Force on Climate-related Financial Disclosures

Governance

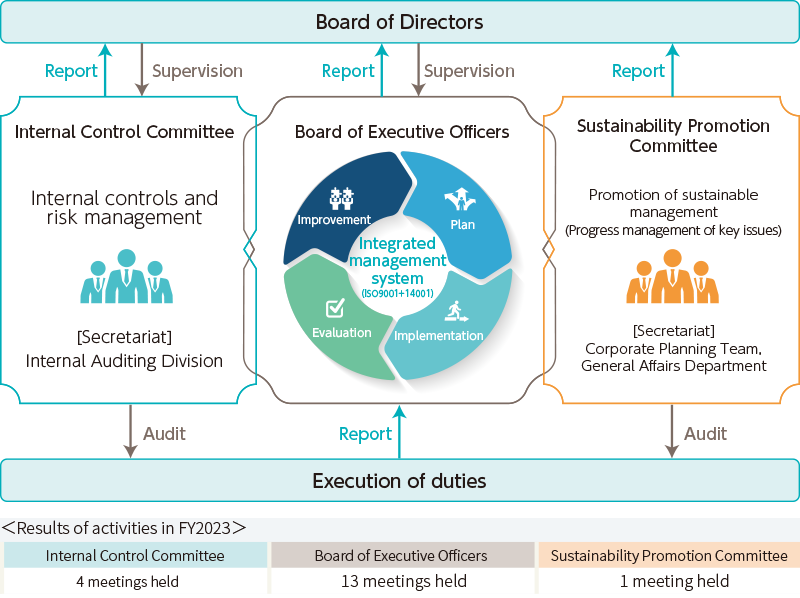

In promoting sustainable management, the Group established the Sustainability Promotion Committee in January 2024, chaired by the President and Representative Director. The Committee will convene quarterly (four times a year) to deliberate and supervise basic policies, business activities and strategies related to sustainability, and report to the Board of Directors. The Board of Directors and this Committee will set goals and plans, manage their progress and make investment decisions taking climate change issues into account.

Strategy

Following the framework advocated by the TCFD, the Group has identified and evaluated the future impacts of climate change on its business using the scenario analysis approach. We are now working to calculate climate-related quantitative financial impacts and consider measures to address risks and opportunities.

Risk management

Process for screening, assessing and managing climate-related risks

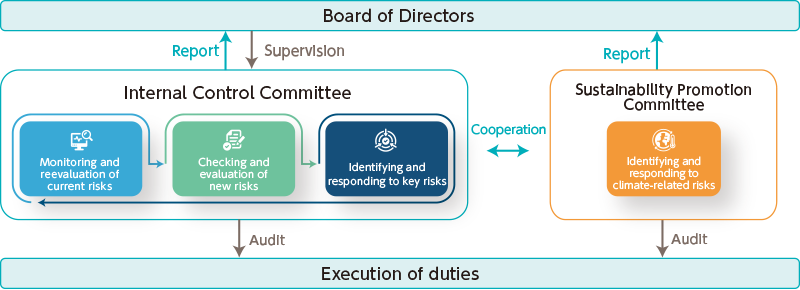

Risks and opportunities are identified based on ISO 14001 environmental aspects (factors that directly and indirectly affect the environment), environmental laws and regulations, issues in the industry and business environment, and stakeholder needs and expectations. The Sustainability Promotion Committee identifies risks and opportunities related to climate change and the Internal Control Committee identifies business risks and other risks at least once a year.

Taking into account the risks and opportunities related to climate change, each department sets its own environmental targets and acts in accordance with the ISO integrated management system. The progress in achieving environmental targets is monitored by the Sustainability Promotion Committee, which meets quarterly, and reported to the Board of Directors at least once a year.

Integrated risk management

The identification, evaluation, and determination of policy for specific risks facing the Group is the role of the Internal Control Committee. Climate-related risks and opportunities and their countermeasures are submitted by the Sustainability Promotion Committee to the Internal Control Committee and integrated into company-wide risks. The Internal Control Committee meets four times a year under the supervision of the Board of Directors and is chaired by the Representative Director and President.

Indicators and targets

As part of our response to climate change, the Group aims to become carbon neutral by 2050. We will strive to reduce greenhouse gas emissions, promote the efficient and sustainable use of energy, and develop and provide products and services that contribute to climate change mitigation and adaptation. These indicators and targets are described in the Environmental Policy formulated in 2024, which is posted on our website.

Greenhouse gas emissions (calculation of Scopes 1, 2, and 3)

The Group has been promoting the understanding of greenhouse gas emissions, and as part of our efforts in this fiscal year, we calculated Scope 1, Scope 2, and Scope 3 in FY2024, in addition to Scope 3 in FY2023, covering the Company and its major consolidated subsidiaries. A breakdown is presented in the table below.

Unit: t-CO2

| FY2021 | FY2022 | FY2023 | FY2024 | ||

|---|---|---|---|---|---|

| Scope1 | Business operator’s direct greenhouse gas emissions | 4,533 | 5,459 | 5,443 | 9,704 |

| Scope2 (Market standards) |

Indirect emissions associated with the use of electricity, heat, and steam supplied by other companies | 6,109 | 6,000 | 5,877 | 5,839 |

| Scope2 (Location standards) |

5,287 | 5,153 | 5,007 | 5,046 | |

| Subtotal of Scopes 1 + 2 (Market standards) | 10,642 | 11,459 | 11,320 | 15,543 | |

| Subtotal of Scopes 1 + 2 (Location standards) | 9,820 | 10,612 | 10,450 | 14,750 | |

| Category 1 | Purchased goods and services | - | 596,126 | 588,199 | 622,475 |

|---|---|---|---|---|---|

| Category 2 | Capital goods | - | 5,180 | 2,714 | 5,881 |

| Category 3 | Energy-related activities | - | 1,670 | 1,610 | 2,242 |

| Category 4 | Upstream transportation and distribution | - | 1,960 | 1,749 | 1,879 |

| Category 5 | Waste | - | 12 | 12 | 21 |

| Category 6 | Business travel | - | 200 | 206 | 202 |

| Category 7 | Employee commuting | - | 532 | 554 | 540 |

| Category 13 | Downstream leased assets | - | 16 | 15 | 15 |

| Scope 3 | Other companies’ emissions related to business activities | - | 605,696 | 595,059 | 633,254 |

| Total of Scopes 1 + 2 (Market standards) + 3 (Supply chain emissions) | - | 617,155 | 606,379 | 648,797 | |

| Total of Scopes 1 + 2 (Location standards) + 3 (Supply chain emissions) | - | 616,308 | 605,509 | 648,003 | |

Calculation of Scopes 1 and 2

- * Scopes 1 and 2 were calculated in line with GHG Protocol.

The calculations of Scopes 1 and 2 covered main locations in Japan, including those of consolidated subsidiaries. In principle, business locations and sales offices were not included in the calculations of Scopes 1 and 2. - * The calculation method, emission factors, etc. for Scopes 1 and 2 are based on the Calculation, Reporting, and Publication System for Greenhouse Gas Emissions Disclosure, which is based on the Act on Promotion of Global Warming Countermeasures.

The “List of calculation methods and emission factors for calculation, reporting, and publication system,” the adjusted emission factors (Scope 2 market standards) and national average factor (Scope 2 location standards) from the “List of emission factor of each electric power supplier,” and the “List of GWP by refrigerant type used for calculation and reporting of CFC leakage” are used. - * From FY2022, calculations include CFC emissions.

- * FY2023 figures have been recalculated and updated based on actual energy consumption from January to March 2024.

- * From FY2024, calculations include fuel consumption related to deliveries by consolidated subsidiaries.

Calculation of Scope 3

- * Scope 3 was calculated in line with GHG Protocol. Scope 3 is calculated based on basic consolidation, and Category 5 is calculated only for those sites where data could be collected.

- * The calculation method, emission factors, etc. for Scope 3 are based on the “Basic Guidelines on Accounting for Greenhouse Gas Emissions Throughout the Supply Chain” and “IDEA v2.”

- * Emissions for Categories 6 and 7 for FY2022 have been recalculated and updated.

- * Category 8: Applicable activities have already been accounted for in Scopes 1 and 2.

- * Categories 9 to 12 and 15: Calculation will be considered in the future.

- * Category 14: Not applicable.

Water security

The Group has incorporated “conservation of water and fishery resources and promotion of resource recycling” into its Environmental Policy. We are working to promote the sustainable use and reduction of water and fishery resources used in our supply chain, with the aim of realizing a cycle-oriented society.

Monitoring of water use and reduction targets

We began monitoring our water usage in FY2023. We understand that approximately 90% of water used within the Group is attributable to food manufacturing subsidiaries.

Our target for water usage is to reduce water intake by 10% by 2030 (compared to results for FY2023).

Unit: m3

| FY2023 | FY2024 | Reduction rate |

|

|---|---|---|---|

| Water intake |

210,487 | 240,069 | -14.1% |

| Water discharge |

205,434 | 235,349 | -14.6% |

| Water consumption |

5,053 | 4,720 | 6.6% |

Water risk assessment

We assess each of our business sites in Japan using WRI Aqueduct* and have confirmed that water stress at all sites is either low (less than 10%), low to medium (10-20%), or medium to high (20-40%).

- * WRI Aqueduct: A water risk analysis tool for various regions around the world provided by the World Resources Institute (WRI).

Conserving fishery resources

Acquisition of Marine Eco-Label (MEL) certification

Nichimo works to provide safe, sustainable food in harmony with the marine environment by conserving fishery resources and ecosystems and establishing traceability. As part of these efforts, in May 2021, the Company acquired MEL certification from the Marine Eco-Label Japan Council for the distribution processing stages of processed coho salmon farmed in Miyagi Prefecture.

Marine Eco-Label Japan (MEL) certifies that companies in the fishing and aquaculture industries are conserving resources and ecosystems so that these can be optimally used by generations into the future. Certified products are distributed with the MEL logomark. MEL’s mission is to “help protect the richness of the seas and contribute to new development of Japan’s marine products industry and to the achievement of the SDGs.” MEL, which is approved by the Global Sustainable Seafood Initiative (GSSI), is a de facto international sourcing standard, having been adopted by major retailers and other companies around the world, and is expected to help improve international reputations and contribute to the promotion of more exporting.

Within the Group, Nichimo Mariculture Co., Ltd. obtained certification in April 2020 at the production stage for coho salmon farmed in Miyagi Prefecture, a goal that has been worked on for many years. The Company also acquired certification to integrate production and sales, thereby realizing a system for supplying sustainable marine products.

Acquisition of Marine Stewardship Council Chain of Custody (MSC CoC) certification

There are two types of MSC certification: MSC Fisheries certification for companies that engage in sustainable fishing operations that are properly managed in terms of consideration for fishery resources and the environment, and MSC CoC certification for the supply chains used to reliably deliver the marine products of MSC-certified companies in the fishing industry to consumers. Marine products featuring the blue MSC label are sourced by companies in the fishing industry certified by an independent examining authority as taking proper considerations for fishery resources and the environment.

The Company acquired MSC CoC certification for its handling of MSC-certified pollack roe, crab, and fresh and frozen products, and supplies both whole and processed foods to contribute to the supply of sustainable marine products with consideration for fishery resources and the environment.

Introducing energy-saving,

eco-friendly equipment

Fried tofu maker with a heat exchange fryer

Nichimo is making progress with efforts to introduce energy-saving, eco-friendly equipment. For example, for the tofu fryers on fried tofu production lines, the Company uses heat exchange equipment—over 40% more thermally efficient than the conventional open-flame fryers—to reduce running costs, save energy, and cut CO2 emissions.

The Company also supplies equipment for removing the steam and oily smoke generated by cooking to reduce foul odors emitted from factories and contribute to the conservation of living environments in the communities around them.