Special Feature 1

Today, the marine products industry is facing a variety of problems. The number of people employed in the domestic fishing and marine products industries is on the decline, and labor shortages are becoming more serious. Additionally, the discharge of plastic marine waste and rising ocean temperatures are said to be causing major impacts on ocean ecosystems around the world.

In response to these issues, the Company is working to reduce the labor and power required for fishing and to develop and supply systems that increase the added value of caught marine products, as well as environmentally friendly marine materials, in order to pass on a better fishing industry and marine environment to the next generation.

Improving Working Conditions and Increasing Added Value

Contributing to better working conditions in the fishing industry and the higher added value of marine products

Coho salmon sedated using our seafood sedation system

Not only does the fishing industry have harsh working conditions, but the labor shortage is becoming more serious as the workforce ages. In response to these issues, the Nichimo Group aims to contribute to improving the working environment of fishing companies, while also increasing the added value of marine products and creating a sustainable fishing system.

Coho salmon sedated using our seafood sedation system

Providing a system to support fishing companies

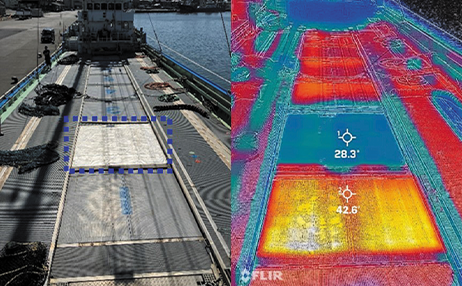

Left: The blue dotted line indicates the cold storage hold covered with SPACECOOL

Right: Temperature measurement using a thermograph

The seafood sedation system developed by the Group temporarily sedates marine products by passing a weak electric current through them, making it possible to shorten the time required for size sorting and live-killing. In addition, this system keeps the fish calm during the live-killing process, preventing a decline in quality due to bruising. The ability to sell these marine products with the added value of “high quality” means expected higher profits. This has attracted attention from fishing companies across the country, leading to the more widespread adoption of this system.

Additionally, the extreme heat caused by climate change in recent years has caused temperatures to rise in fishing boats’ cold storage holds (spaces where ice is stored to cool fish after they are caught), increasing the rate at which the ice melts. This has become a concern for fishing companies, as it is becoming difficult to use ice as planned. To solve this issue, the Company was the first in the fishing industry to use a radiative cooling material called SPACECOOL, which reduces temperatures by releasing heat into outer space. We have confirmed that when SPACECOOL is used to cover the door of a cold storage hold, the temperature inside dropped by approximately 3°C compared to when it was covered with a conventional cooling sheet. The use of this material has led to more economical and planned use of ice, contributing to more efficient fishing. Furthermore, compared to before, marine products can now be landed at a fishing port with its freshness still intact, leading to greater added value.

Aiming to become a marine solutions company

We are leveraging our advanced technology and know-how as a fishing gear manufacturer for over 100 years to provide solutions that contribute to fishery symbiosis, such as regional development using offshore wind power generation. Going forward, the Group will continue to contribute to the further growth and stabilization of the fishing industry and to realizing sustained profitability.

Development of Environmentally Friendly Fishing Gear

Development and provision of environmentally friendly fishing gear materials

A sea turtle tangled in a fishing net

Today, the problem of waste originating from plastics is growing worse in oceans around the world. Among these, significant damage is caused by issues such as ghost fishing, which refers to marine creatures becoming entangled and killed by fishing nets and gear that have been illegally dumped or washed away in heavy weather. The plastic waste also obstructs vessel travel, causing economic loss by creating obstacles to ocean navigation and hindering vessel traffic.

A sea turtle tangled in a fishing net

Addressing marine pollution caused by marine plastic waste

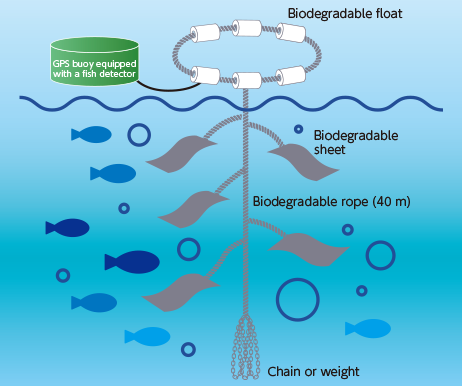

Biomass/biodegradable-based fishing gear

To address these issues, the Group is working to develop environmentally friendly marine materials made from biomass materials that are biodegradable in the natural environment. Fishing gear materials made from this material will sink to the bottom of the ocean where it will undergo hydrolysis, which will promote microbial degradation by bacteria, thereby easing the problem of plastic waste in the ocean.

Currently, we are expanding the use of materials such as nets and ropes made from biodegradable material for land use. We are also looking to roll them out in products geared toward the mountains and forests that create rich oceans.

Working to create blue carbon

Kelp grown using biomass and biodegradable marine materials

Global reduction measures are needed for emissions of greenhouse gases, particularly CO2, a factor in global warming that causes rising ocean temperatures. With a goal to achieve carbon neutrality by 2050, the Company is now working actively on various fronts to reduce CO2 emissions.

As part of these efforts, we are working to absorb CO2 from the atmosphere and fix it in the ocean by cultivating seaweed, such as mozuku and kelp, to create blue carbon. Test results have shown that by attaching seaweed spores to biomass-based, biodegradable ropes and nets underwater, their initial growth rate is four to five times faster than that of similar materials made from general petroleum.

Currently, biomass-based, biodegradable ropes and sandbags are being used in kelp aquaculture in Kamaishi City, Iwate Prefecture, helping to prevent rocky shore denudation of algae beds caused by the mass proliferation of sea urchins.

Furthermore, it is estimated that compared to petroleum-based netting, combined CO2 emissions from raw material procurement, production and disposal can be reduced by approximately 40%. In addition to promoting the creation of blue carbon, the Group is also working to reduce CO2 emissions, the main cause of global warming, and to realize a sustainable marine environment.